Pressure Sensitive Labels

Pressure sensitive labels (PS labels) are the most widely used type of printed labels in manufacturing today. These self-adhesive labels work through a pressure-activated adhesive system—no heat, water, or solvents required. They're ideal for both automated applicator lines and hand application. By industry estimates, pressure sensitive labels make up roughly 80% of the global label market.

As a pressure sensitive label manufacturer, Midwest Label Supply works with OEMs, contract packagers, and product companies who need precision labels that perform. We print on short-run and long-run quantities with variable data capabilities. Our experience spans specialty inks, industrial adhesives, and substrates including paper, film, foil, and synthetic materials. The adhesive layer bonds instantly under light pressure from a labeling machine or by hand—peel from the liner and apply.

What are Pressure Sensitive Labels used for?

Custom pressure sensitive labels are most commonly thought of when manufacturers are considering how the label will be applied to the packaging of a product. Often times pressure sensitive labels will be applied to the packaging through an automated or semi-automated process. Such as a cylindrical beer or soda can or bottle label applicator. You will find pressure sensitive labels on a broad variety of products. At MLS custom pressure sensitive labels are manufactured for wine labels, cosmetic labels, medical labels, beer labels and more.

Variable Pressure Sensitive Labels

Midwest Label Supply can print serialized and variable custom data on your next label. Types of codes we can produce include QR codes, data matrix codes, bar codes, and warehouse SKU labels. Just provide us with an excel, CSV or txt file and we can input the data into labels. We are able to do short-run or long-run applications.

Custom Pressure Sensitive Labels

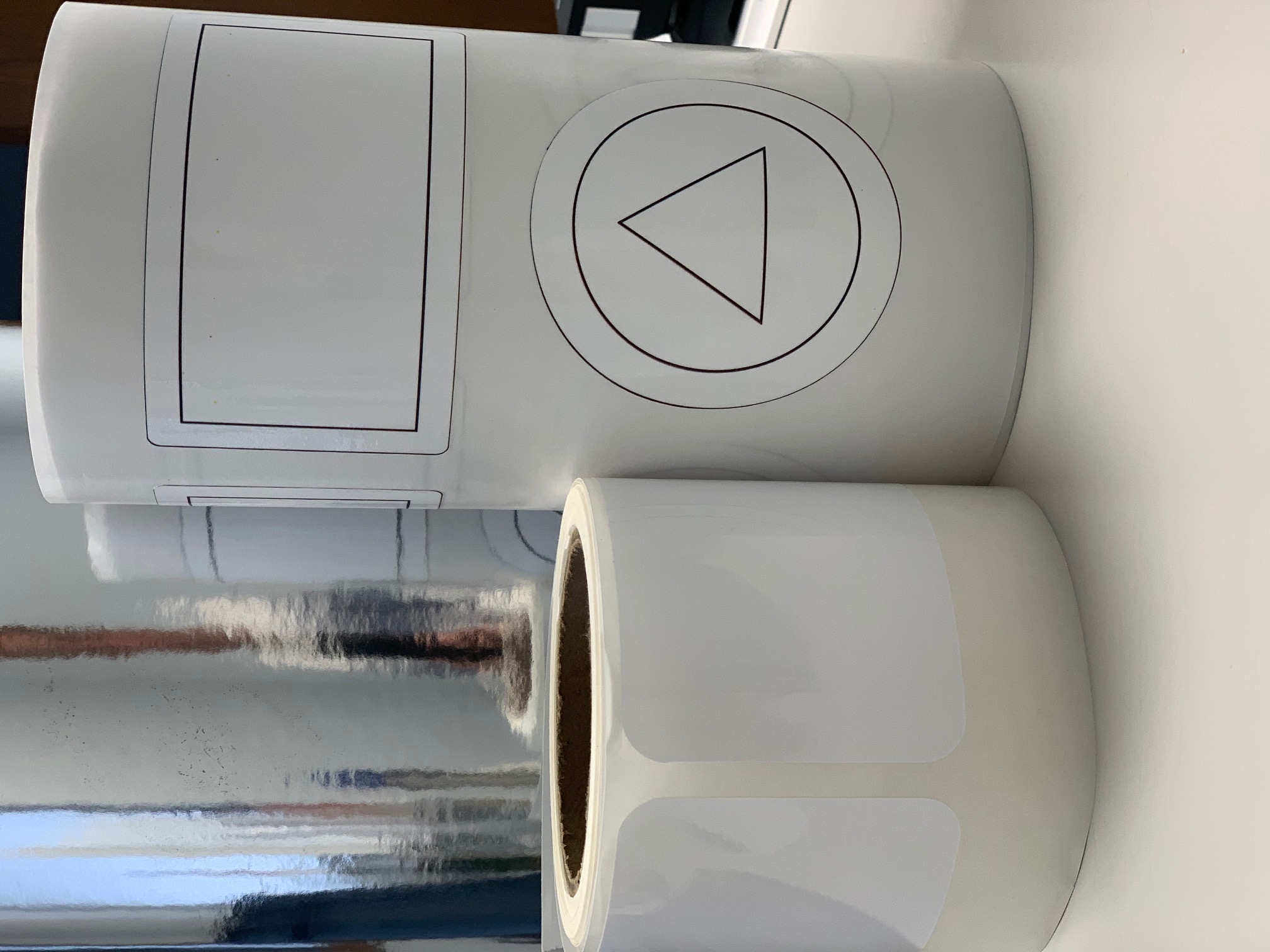

Midwest Label Supply offers print on demand custom pressure sensitive label printing. We are able to do short-run or long-run applications. We can also do variable printing for batch or 1 labels or mass customization applications (e.g. Give someone a Coke campaign). We can add laminates which protect labels from moisture or add tactile touch and feel. The sizes vary from 10mm x 10mm to 1200mm x 2000mm sheet sizes and 10mm to 1000mm discs diameters.

Pressure Sensitive Label Finishing

Along with providing a vast array of printing options for custom pressure sensitive labels, we also can do a variety of unique custom finishing options. Some examples include die cutting such as the Coors Mountain label. We can provide overlaminate for UV protection, limiting abrasion and moisture protection. Lastly we can slit the labels onto roll sizes that fit your custom needs. As a contract print manufacturer we do not store off-the-shelf PS labels, instead our labels are made to order.

Pressure Sensitive Food and Beverage Labels

You'll see our custom pressure-sensitive labels on an expansive scope of items from food and beverage to industrial equipment to cold wet ice cream shelves. Our specialty is low volume specialty products. We have a fine eye for the print craft and we hope our customers do as well. We work with a variety of specialty products that need to stand out on the shelves.

Below is a video of our die cutting, splicing and roll-to-roll finishing at work:

Pressure Sensitive Adhesive Technology

The "pressure sensitive" part comes from the adhesive layer itself. Unlike traditional adhesives that need heat activation or curing time, PS adhesives form an immediate bond through van der Waals forces when pressure is applied. We work with three main adhesive chemistries:

- Acrylic adhesives — UV stable, good chemical resistance, ideal for outdoor and industrial labels

- Rubber-based adhesives — High initial tack, good for rough surfaces and cold temperature application

- Silicone adhesives — Extreme temperature range (-65°F to 500°F), used in aerospace and specialty applications

Each adhesive can be formulated as permanent, removable, or repositionable depending on your application requirements.

Custom Pressure Sensitive Options

We print on over 50 substrate options spanning paper, film, and foil categories with matching adhesive and laminate configurations.

Face Stock

Face stock options include matte paper, gloss paper, semi-gloss, vinyl, BOPP (biaxially oriented polypropylene), polyester, foil, and specialty films. Different substrates offer different performance characteristics—vinyl for durability, BOPP for moisture resistance, polyester for chemical exposure.

Adhesive Selection

Adhesive selection matters. Cold or wet environments need aggressive adhesives with high initial tack. Removable applications need clean-release formulations. Food contact applications require FDA-compliant adhesives. We'll match the adhesive to your substrate, surface energy, and environmental conditions.

Finishing

Finishing options include precision die-cutting, matte and gloss laminations for UV protection, and custom slitting to match your applicator specifications. We can slit to any core size and roll diameter your equipment requires.

MLS's food packaging pads have a market advantage in that by design they are versatile enough to be produced to:

MLS printing and converting is a Milwaukee based pressure sensitive label manufacturer, contact us today with your custom label needs.